Models for the Overhead Projector

- Clutches, Transmission, Synchromesh, Automatic Transmission

Models for the Overhead Projector

|

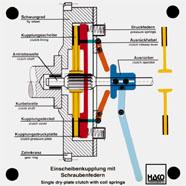

Order No. 115

- motion shown when pressure plate is lifted |

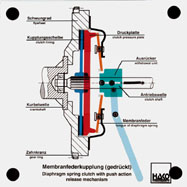

Order No. 116

- motion shown when the pressure plate is lifted |

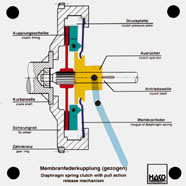

Order No. 117

- characteristics of a pulled clutch in motion |

|

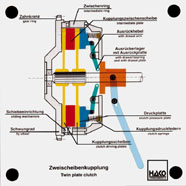

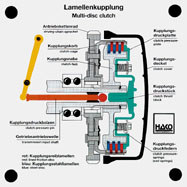

Order No. 207

- function of a double-disk clutch |

|

Order No. 293

- pressing the clutch pressure pin by means of the lever |

|

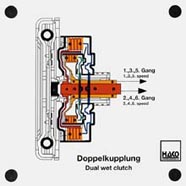

Order No. 470

- Function of a dual wet clutch with disks |

|

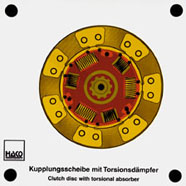

Order No. 447

- Purpose of the torsion-bar suspension |

|

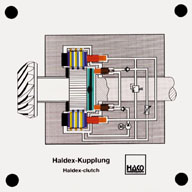

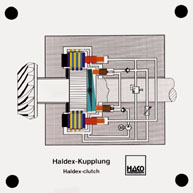

Order No. 429

It replaces the viscous clutch in four-wheel drive. As soon as a

difference in speed comes about between front and rear axle, the

swash plate begins to turn. In this, it operates the pump

plunger, which presses hydraulic oil into the plunger of the

friction disks. |

|

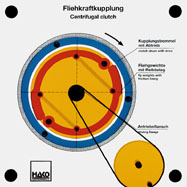

Order No. 295

- turning the driving crank sets the driving flange into motion

|

|

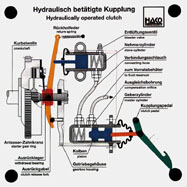

Order No. 279

- interaction of master cylinder and slave cylinder |

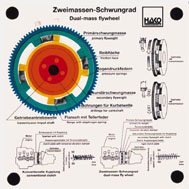

Order No. 275

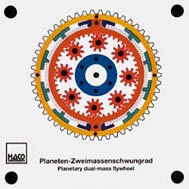

- design of a dual-mass flywheel |

|

|

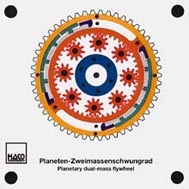

Order No. 469

- Rotation of the secondary flywheel mass against the primary

flywheel |

|

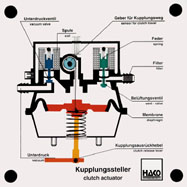

Order No. 324

- function of the solenoid valves |

|

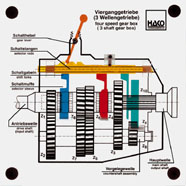

Order No. 199

- this model facilitates the understanding of a modern car

transmission |

Order No. 201

"reverse gear" |

|

|

|

|

|

|

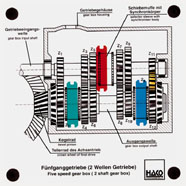

Order No. 202

- power distribution in a five-speed transmission |

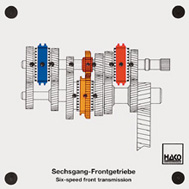

Order No. 466

- shifting the six forward gears by displacing the gearshift

sleeves |

|

|

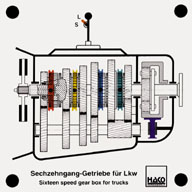

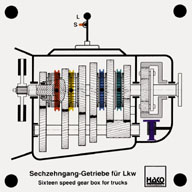

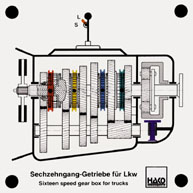

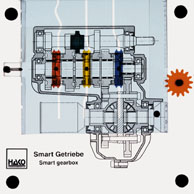

Order No. 438

The basic module comprises a gearbox with four gears. By adding

a front-mounted and a rear-mounted module, a sixteen-speed

gearbox results. With the help of the left-hand sleeve, the ... |

|

|

|

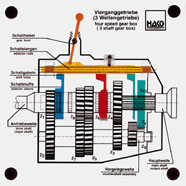

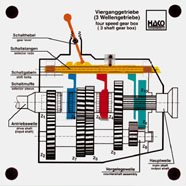

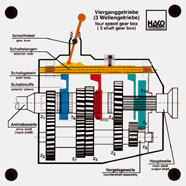

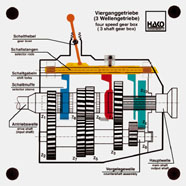

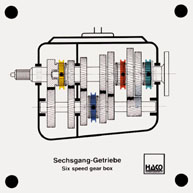

Order No. 433

This gearbox is ideal for demonstrating the power flow in the

individual gears. The shifting sleeves are distributed to both

main shafts. A fourth shifting sleeve was required for the

synchronised reverse gear. |

|

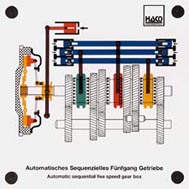

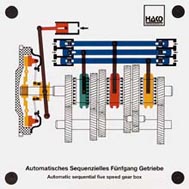

Order No. 467

- function of an automatic sequential transmission |

|

|

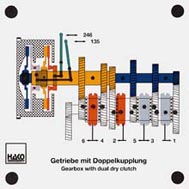

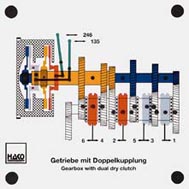

Order No. 465

- operation and function of both clutches |

|

|

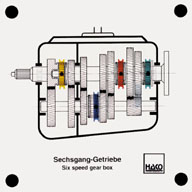

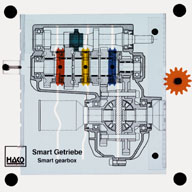

Order No. 432

This new construction by the firm of GRETAG shows a mechanical

manual transmission with six forward gears and one reverse gear.

A gear selector drum driven by an electric motor operates the

shifting. |

|

|

|

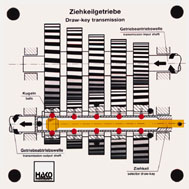

Order No. 270

- function of a draw-key transmission |

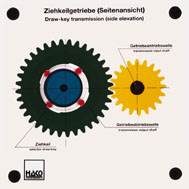

Order No. 278

(section of side view) |

|

|

Order No. 451

- Flow of force in the shift dog transmission |

|

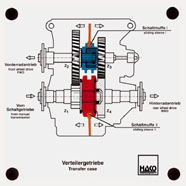

Order No. 203

- power distribution in a transfer case |

|

Order No. 144

-gearshift rod with gearshift fork in motion |

|

|

|

Order No. 439

- Movement of gearshift rod and gearshift fork |

|

|

|

Order No. 400

- moving the gearshift fork and sliding sleeve |

|

|

|

Order No. 186

"idle position" |

|

|

|

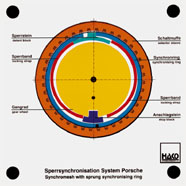

Order No. 164

- dragging of the split synchronizing ring |

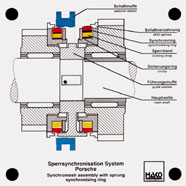

Order No. 204

- this longitudinal section of a locking synchronization

facilitates the understanding of model #164 |

|

|

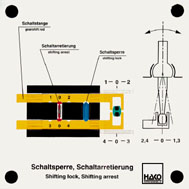

Order No. 371

The shifting arrest prevent 2 gears from being selected

simultaneously by locking the other gearshift rod.

Demonstration: that the simultaneous selection of two gears is

not possible. |

|

|

|

Order No. 430

Functions: |

|

|

|

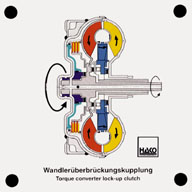

Order No. 462

The model shows the turbine wheel, the pump wheel and the stator

on one level. |

... favourable angle by the stator. There is an increase of the

engine torque. |

The stiffening force and thus also the torque reinforcement

becomes less. |

|

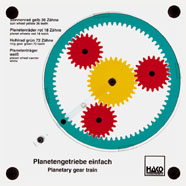

Order No. 239

- all transmission ratios of a simple planetary gear train can

be shown by driving by driving and locking different parts of

the model from the outside |

Order No. 240

Ravigneaux gear set |

Order No. 385

- Two simple planetary gear sets are combined to formed a

single set. The Simpson gear set has 2 ring gears, 2 planet

carriers and two connected sun wheels. Various gears (forwards

and reverse) can be selected. |

|

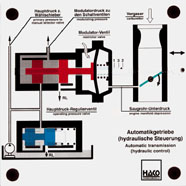

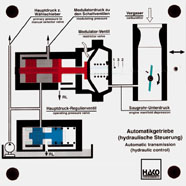

Order No. 215

Principles of an automatic transmission |

Order No. 227

- the model shows how pressure variations in the intake

manifold (i.e.load) act on the control piston via a diaphragm;

the control piston influences the shift points of the automatic

transmission |

|

|

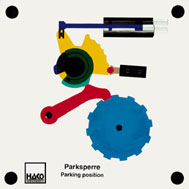

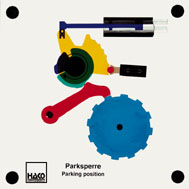

Order No. 372

If the selector lever of an automatic transmission is on "P",

the park position is engaged and prevents the vehicle from

rolling. |

|

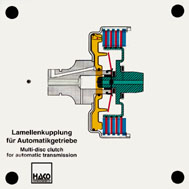

Order No. 373

Hydraulic clutches are necessary for shifting the planetary gear

train. Function of the ventilating system. Power flow: the

piston presses the discs. |

|

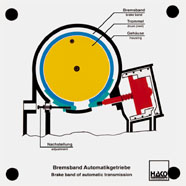

Order No. 179

automatic transmission |

Order No. 384

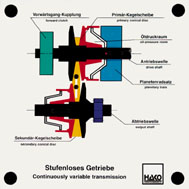

The transfer of power from the primary conical disc to the

secondary conical disc is made by means of the sliding

articulated band. |

|

|

Order No. 229

The gear drive without backlash, mainly used for motor bikes,

has on one shaft a gear wheel with 49 teeth and another gear

wheel with 50 teeth. The two are axially preloaded against each

other. With every rotation, the gear wheel with 49 teeth is

turned one tooth farther than the gear wheel with 50 teeth. This

causes a gear drive without backlash.

|

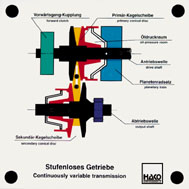

Order No. 448

Infinite transmission for rear-wheel driven cars, suitable up to

500 Nm. A roll is used for the force transmission. Pivoting the

roll alters the gear ratio infinitely.

|

|

|

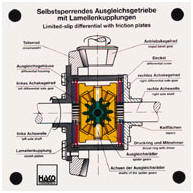

Order No. 269

with friction plates |

|