Models for the Overhead Projector

- Combustion Engines, Steam Engines, Stirling Engines, Engine Management,

Other

Models, Model Stand and Model Cabinet for OHP-Models

Models for the Overhead Projector

|

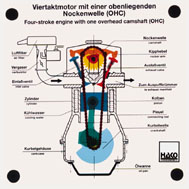

Order No. 101

- drive of the double overhead camshaft |

Order No. 255

- crankshaft drive, stroke of a piston |

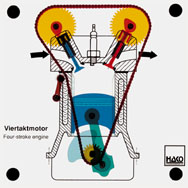

Order No. 417

- all the functions of a four-stroke engine can be shown with

valve overlap |

|

|

Order No. 102

- function of combustion chamber and crankcase |

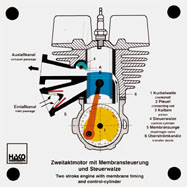

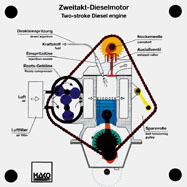

Order No. 193

- principle of a modern two stroke engine |

Order No. 398

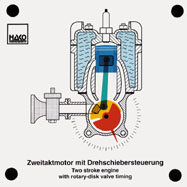

- gas control in a two-stroke engine with rotary-disk valve |

|

|

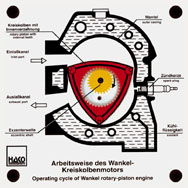

Order No. 191

-

the OHV-engine is driven by means of a crankshaft, tappet and

rocker arm |

Order No. 287

- function of crankshaft drive |

Order No. 238

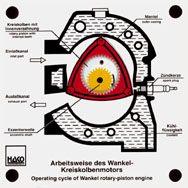

- the bid and solid overhead model shows how a Wankel engine

works, especially the function of an eccentric shaft and gearing |

|

|

|

Order No. 301

The two engines are connected by gear wheels and are turning

simultaneously |

|

|

|

Order No. 283

- function of the piston and flywheel |

|

Order No. 289

- function of a rhomboid gear-set |

|

|

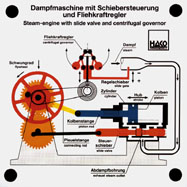

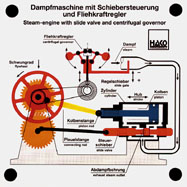

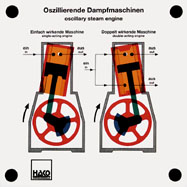

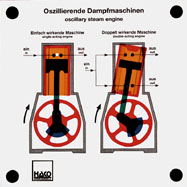

Order No. 319

the simplest form of a reciprocating engine is a steam engine

with oscillating cylinders. The model shows both the

single-acting and the double-acting engine. The mode of

operation of the engine and the control of steam inlet

... |

|

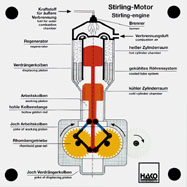

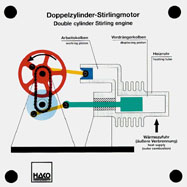

Order No. 304

- function of a double-cylinder Stirling engine |

|

|

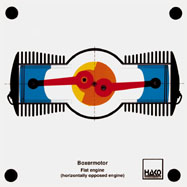

Order No. 104

- characteristics of a flat engine in motion |

Order No. 105

- arrangement of the cylinders |

Order No. 103

- function of a the master connecting rod |

|

|

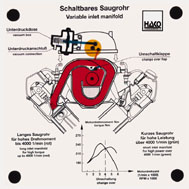

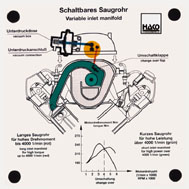

Order No. 420

- function of a radial engine according to the four-stroke

principle |

Order No. 457

(SVC engine) |

|

|

|

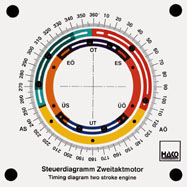

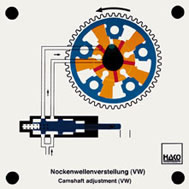

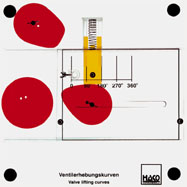

Order No. 395

- the opening and closing angle of the discharge and inlet

valves can be adjusted as required |

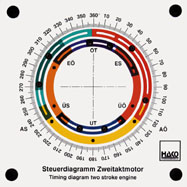

Order No. 399

Setting the various angles for: |

|

|

|

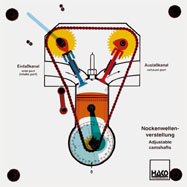

Order No. 187

all functions of a four stroke engine can be shown, incl. chain

tensioning. Inlet valve and exhaust valve openings can be read

in degrees. Valve opening and closing as well as valve

overlapping can be shown. The inlet cam can be advanced by means

of a lifting cam and power screw. |

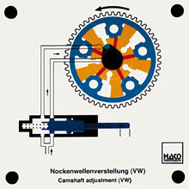

Order No. 235

Advancing the inlet camshaft by means of two sliding chain

tensioners, which can be moved to and from via magnetohydraulic

actuation. The exhaust camshaft is driven by the crankshaft. The

inlet camshaft is driven by the outlet camshaft via a chain. |

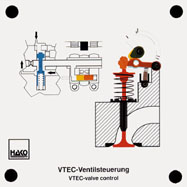

Order No. 419

- valve control in the lowest speed range with drag levers

released |

|

|

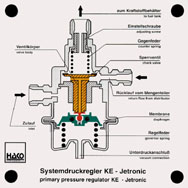

Order No. 463

In this, the adjustment of the inlet and the outlet camshaft is

done with the help of hydraulically operated vane adjuster. In

an outer rotor, an inner rotor is rotated hydraulically

clockwise or anti-clockwise and adjusts the camshaft in the

direction of early or late. |

The maximum adjustment angle is 52° crank angle with the inlet

camshaft and 22° with the outlet camshaft. |

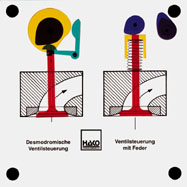

Order No. 130

- function of the desmotronic valve actuation (with cams to open

and close the valve) |

|

|

Order No. 435

Functions: |

|

|

|

|

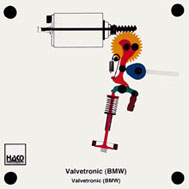

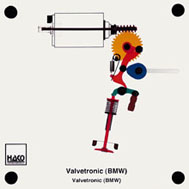

Order No. 460

Instead of a throttle valve, the differing valve stroke is used

in the Valvetronic to control the fresh gas. An eccentric shaft

is operated by the engine management via an electric motor, a

worm and a work wheel. |

The eccentric shaft controls an oscillating lever between the

cam shaft and the rocker arm, with the result that the cam of

the inlet camshaft opens the valve to differing extents (from

zero stroke up to maximum stroke). |

Fig. 1: Zero stroke (valve remains closed) |

|

|

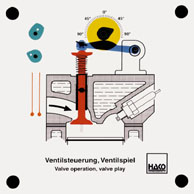

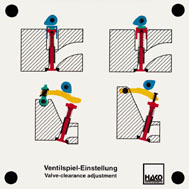

Order No. 390

It is possible to demonstrate 4 different ways of setting the

valve clearance, by rotating the adjusting screws on the rocker

arm or rocker lever, by inserting discs of varying thickness or

by means of an eccentric on the rocker arm. |

Order No. 391

It is possible to demonstrate 4 different ways of setting the

valve clearance. By inserting discs of varying thickness in or

under the bucket tappet. By rotating the adjusting screws on the

rocker arm and rocker lever. |

|

|

|

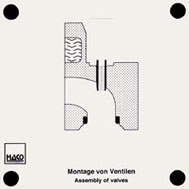

Order No. 464

The assembly of a valve into the

cylinder head can be demonstrated clearly: |

- Insertion of the valve shaft into the sleeve on the cylinder

head Pushing the valve shaft sealing on |

- Pushing the spring valve and the spring cap on Pushing the

spring valve over the spring cap Pushing the valve key into

the groove of the spring cap |

|

|

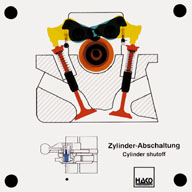

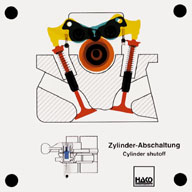

Order No. 434

The cylinder shutoff, a new development for the new Daimler Benz

S class, is switched on and off electro-hydraulically by the

control unit. In the lower load area, 4 cylinders are switched

off, in the upper load area there is a switch-over to 8

cylinders. The valves are operated in a locked state. If the

coupling pins ... |

|

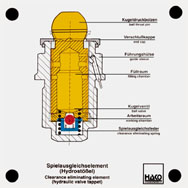

Order No. 131

- how the hydraulic valve tappet works under pressure and

release |

|

|

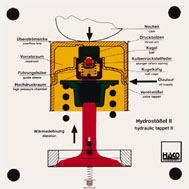

Order No. 268

This hydraulic tappet is designed as a bucket tappet and makes a

valve adjustment without clearance possible. Function of high

pressure chamber, ball valve, clearance-eliminating spring and

valve tappet can be shown. |

Order No. 459

The following can be shown: |

|

|

|

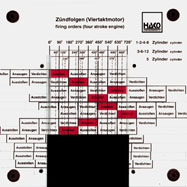

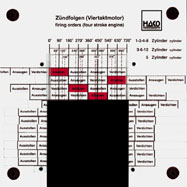

Order No. 145

- firing order of one- to twelve-cylinder engines |

Order No. 145 E |

||

|

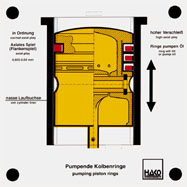

Order No. 250

- inserting three different piston rings shows an incorrect and

correct ring gap |

|

Order No. 211

- when moving the pistons to and from, you can see how the

piston rings slide up and down in the grooves if there is too

much clearance: Oil is pumped into the combustion chamber |

|

|

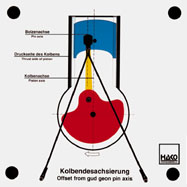

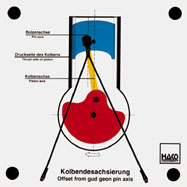

Order No. 146

- without offset: piston changes bearing surface after TDC |

|

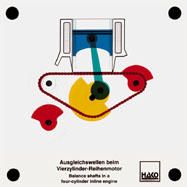

Order No. 189

- the two balance shafts of a four-cylinder inline engine

turn towards each other with double crankshaft RPM |

|

|

Order No. 276

Functions: |

|

Order No. 196

The filling curves of three different cam shapes can be drawn

directly on a mobile slide by means of the three enclosed felt

pens (red, blue and green). |

|

|

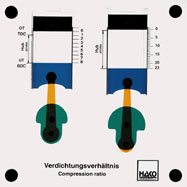

Order No. 337

Working out of the different capacities: |

|

|

|

|

Order No. 1015

- for storing approx. 50 to 60 OH models (depending on

height), made of synthetic - laminated chipboard, lockable |

Order No. 1014

-

for storing 10 OH models made of veneered plywood |

||