Refrigeration

R434 Vortex Tube Refrigerator

A fully instrumented bench top vortex tube refrigerator having no moving parts and requiring only a compressed air or other suitable gas supply to operate.

These units are normally used in specialised cooling applications where simplicity, reliability and compactness are required. From compressed air at ambient temperature and a high speed rotating vor tex, the unit produces air temperatures down to -20°C, can perform 75 watts of cooling and discharges a hot air stream at up to 70°C.

A fully instrumented bench top vortex tube refrigerator having no moving parts and requiring only a compressed air or other suitable gas supply to operate.

These units are normally used in specialised cooling applications where simplicity, reliability and compactness are required. From compressed air at ambient temperature and a high speed rotating vor tex, the unit produces air temperatures down to -20°C, can perform 75 watts of cooling and discharges a hot air stream at up to 70°C.

R534 Thermo-Electric Heat Pump

A fully instrumented semi-conductor thermo-electric device demonstrating both power generation and refrigeration from the same bench mounted module.

To demonstrate power generation a low voltage electric heater provides the high temperature energy source, with the DC voltage being supplied by an internally mounted power supply. When the same DC power is supplied to the device, a heat pump or refrigerating effect is generated depending upon voltage polarity.

Used in specialised applications including the cooling of high performance electronics the unit teaches the refrigeration technologies relating to thermo-electric devices.These include: Refrigeration Effect, Generating Effect, Heat pump Effect, Lenz and Seebeck Effects.

A fully instrumented semi-conductor thermo-electric device demonstrating both power generation and refrigeration from the same bench mounted module.

To demonstrate power generation a low voltage electric heater provides the high temperature energy source, with the DC voltage being supplied by an internally mounted power supply. When the same DC power is supplied to the device, a heat pump or refrigerating effect is generated depending upon voltage polarity.

Used in specialised applications including the cooling of high performance electronics the unit teaches the refrigeration technologies relating to thermo-electric devices.These include: Refrigeration Effect, Generating Effect, Heat pump Effect, Lenz and Seebeck Effects.

R514 Mechanical Heat Pump

A unit illustrating the circuit of a commercial and domestic type heat

pump in which free low grade heat from the atmosphere is upgraded and

delivered at an elevated temperature for hot water or space heating.

Standard refrigeration components are used that are all visible and

logically arranged on the bench-mounted panel. Instrumentation is

provided for the measurement of refrigerant and water mass flow rates,

temperatures, refrigerant pressures and electrical power consumed by the

compressor. A computer linked upgrade for the unit is available.

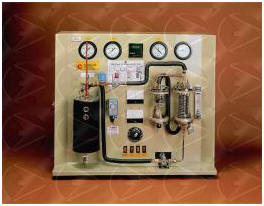

R633 Refrigeration Cycle Demonstration Unit

A bench top vapour compression refrigeration unit fitted with a hermetic compressor, water-cooled flooded glass condenser and evaporator both of similar construction. The unit operates on a low pressure, non-toxic, ozone friendly refrigerant and thereby allows both evaporation and condensation to be safely observed by the students.

Standard instrumentation enables the measurement of all important pressures, temperatures and flow rates. An optional digital temperature indicator upgrade allows plotting of the refrigeration cycle on a pressure-enthalpy diagram. An optional digital wattmeter provides measurement of electrical power input to the compressor and the ability to calculate the Coefficient of Performance (C.O.P.).

A bench top vapour compression refrigeration unit fitted with a hermetic compressor, water-cooled flooded glass condenser and evaporator both of similar construction. The unit operates on a low pressure, non-toxic, ozone friendly refrigerant and thereby allows both evaporation and condensation to be safely observed by the students.

Standard instrumentation enables the measurement of all important pressures, temperatures and flow rates. An optional digital temperature indicator upgrade allows plotting of the refrigeration cycle on a pressure-enthalpy diagram. An optional digital wattmeter provides measurement of electrical power input to the compressor and the ability to calculate the Coefficient of Performance (C.O.P.).

R714 Refrigeration Laboratory Unit

A fully instrumented bench top vapour compression refrigerator with a belt driven compressor, water cooled condenser and variable electrically heated evaporator load. An integral dynamometer allows motor shaft power to be determined. Comprehensive instrumentation allows generation of a complete refrigeration cycle diagram as well as individual component and complete system energy balances.

An optional computerised data acquisition system is available that may be supplied factory fitted or installed as a user upgrade. The Windows software is menu driven and allows data files to be exported to Excel or other spread sheet formats for evaluation and presentation.

A fully instrumented bench top vapour compression refrigerator with a belt driven compressor, water cooled condenser and variable electrically heated evaporator load. An integral dynamometer allows motor shaft power to be determined. Comprehensive instrumentation allows generation of a complete refrigeration cycle diagram as well as individual component and complete system energy balances.

An optional computerised data acquisition system is available that may be supplied factory fitted or installed as a user upgrade. The Windows software is menu driven and allows data files to be exported to Excel or other spread sheet formats for evaluation and presentation.

R832 Air and Water Heat Pump

A bench top air and water heat pump with a water cooled hermetic compressor, water cooled condenser, air source evaporator and water source evaporator using a compact plate heat exchanger. Fully instrumented with all system pressures, temperatures, water and refrigerant flow rates and compressor power input. The unit allows a complete refrigeration cycle pressure-enthalpy diagram to be created as well as heat pump performance curves over a range of condensing and evaporating temperatures.

An optional computerised data acquisition system is available that may be supplied factory fitted or installed as a user upgrade. The Windows software is menu driven and allows data files to be exported to Excel or other spread sheet formats for evaluation and presentation..

A bench top air and water heat pump with a water cooled hermetic compressor, water cooled condenser, air source evaporator and water source evaporator using a compact plate heat exchanger. Fully instrumented with all system pressures, temperatures, water and refrigerant flow rates and compressor power input. The unit allows a complete refrigeration cycle pressure-enthalpy diagram to be created as well as heat pump performance curves over a range of condensing and evaporating temperatures.

An optional computerised data acquisition system is available that may be supplied factory fitted or installed as a user upgrade. The Windows software is menu driven and allows data files to be exported to Excel or other spread sheet formats for evaluation and presentation..

R852 Vapour Jet Refrigerator/Heat Pump

A bench top example of a refrigerator/heat pump that is driven by a heat source. The unit operates on a combined Rankine and vapour compression refrigeration cycle using a low pressure, non-toxic ozone friendly refrigerant. A simple ejector (or thermo-compressor) performs the expansion and compression processes involved in the combined cycles. A small electric motor drives the pump of the Rankine cycle. The heat source is electrically heated and produces high pressure vapour to drive the ejector.

Supplied in standard form with an electric heat source, an optional set of Solar Panels and Installation Package (F820S) is available to demonstrate the generation of a refrigerating effect directly from solar radiation.

A bench top example of a refrigerator/heat pump that is driven by a heat source. The unit operates on a combined Rankine and vapour compression refrigeration cycle using a low pressure, non-toxic ozone friendly refrigerant. A simple ejector (or thermo-compressor) performs the expansion and compression processes involved in the combined cycles. A small electric motor drives the pump of the Rankine cycle. The heat source is electrically heated and produces high pressure vapour to drive the ejector.

Supplied in standard form with an electric heat source, an optional set of Solar Panels and Installation Package (F820S) is available to demonstrate the generation of a refrigerating effect directly from solar radiation.

CBT Computer Based Refrigeration Training

A comprehensive introduction to the vapour compression refrigeration cycle, its history of development, application, analysis and performance.

The software allows individuals to progress at their own pace and enables students to acquire knowledge of the refrigeration cycle before undertaking laboratory experimentation. The content introduces cycle analysis, explains the refrigerant pressure-enthalpy diagram, tabulated refrigerant data and how these may be used to analyse data from a typical refrigeration system. The software also introduces students to industrial refrigeration practice and typical components.

A comprehensive introduction to the vapour compression refrigeration cycle, its history of development, application, analysis and performance.

The software allows individuals to progress at their own pace and enables students to acquire knowledge of the refrigeration cycle before undertaking laboratory experimentation. The content introduces cycle analysis, explains the refrigerant pressure-enthalpy diagram, tabulated refrigerant data and how these may be used to analyse data from a typical refrigeration system. The software also introduces students to industrial refrigeration practice and typical components.